Industry Challenges

LPDDR6 Is Coming: Are You Ready?

6 min

With DDR5, LPDDR5 and even upcoming standards like DDR6 and LPDDR6, the need to probe memory interface signals keeps getting more important. Yet, it is getting even more difficult because of the blistering speeds on both the command buses and the data buses. This is a real industry conundrum that is challenging chip companies, IP companies, system companies, and test vendors such as Introspect Technology. But have no fear! In this article, we’ll look at the most common issues seen in traditional ways of probing, and we’ll share how we’ve optimized probing technology.

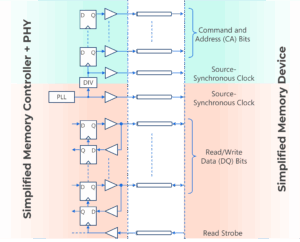

Memory interfaces are highly parallel digital interfaces which enable communication between a controller device, such as a processor, and a memory device. Interfaces such as LPDDR, DDR, and GDDR operate at speeds approaching those of SerDes interfaces like PCI Express, but the number of channels is so much larger. Moreover, as can be seen in Figure 1, memory interfaces are source synchronous, and this complicates testing even further.

First, probing is used for electrical measurement and compliance, especially for chip makers or IP makers. This would allow a user to see how a memory controller operates when a real memory device is connected to it, and how the signals look on a scope, for example. The second application is in the context of protocol validation and debugging. This is used, as an example, for the functional verification of a design and also to ensure compliance with an industry specification and interoperability with another device.

Now, let’s take a look at the two most common probing challenges.

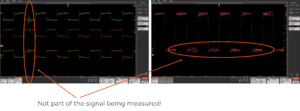

Anytime you have to solder a wire onto a system board or on a characterization board, you are creating an antenna. Probes acting like antennas will pick up electromagnetic interference (EMI), and avoiding these EMI issues altogether is the first challenge. In the waveforms shown in Figure 2, we highlighted two scope waveforms that are a perfect example of how a Wi-Fi burst or a GSM burst couples into the signal being measured and adds to it. So, what we see on the scope is not necessarily the only signal that we’re measuring and it is possible for other things to get coupled into the link as well. Thus, when we put them into a logic analyzer or a BERT, we see bit errors.

A second challenge with probing is what we call return loss, which is an important subject that is often overlooked. When you merely touch a trace with a probe tip, you actually disturb the trace, and as a result, this affects its return loss properties. Probing the trace changes its characteristic impedance and then creates reflections in the waveforms.

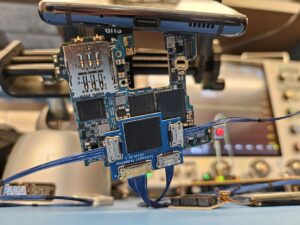

To eliminate these issues and to optimize the probing process, Introspect Technology has created numerous solutions to support engineering teams. From the RSH2 Remote Sampling Head, to Integrated-Tip Interposers (Figure 3), Introspect’s selection of oscilloscope probing solutions are fundamental to helping you probe efficiently and effectively.

With the ever growing DDR and LPDDR market, it is essential for us to support teams developing memory interfaces with cutting edge probing solutions, which are at the height of their own innovative designs. Introspect’s innovative integrated-tip interposer technology addresses EMI and return loss issues. Thanks to multiple probe tips being integrated into a compact design, common probing errors are simply non-existent.

To see a demonstration of live measurements on a smartphone running LPDDR5x at 8533 MTs using Introspect’s Interposer watch our recorded webinar here.

For any inquiries about our DDR & LPDDR solutions or oscilloscope probing solutions, send us an email at info@introspect.ca.